EQUIPMENT

OMAX cuts extremely hard, reflective and nonconductive materials. All materials are cut within .005 of an inch of the desired tolerances using state of the art nozzles. Garnet is mixed with water that enables the materials to be cut and gives the material a smooth clean edge finish as well as efficiently allowing for any additional processing, such as powder coating and welding.

-

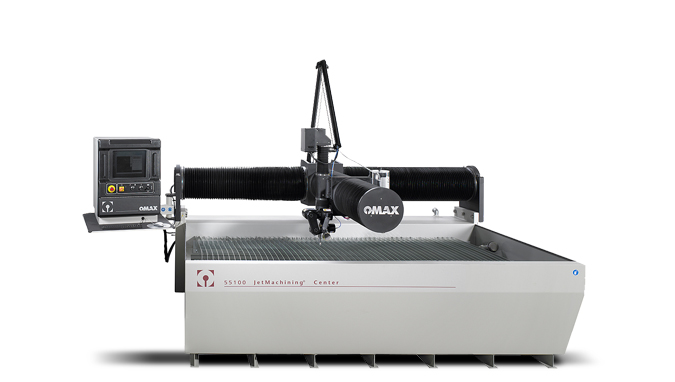

OMAX 55100

- 55″ x 100″ cutting envelope

- Tolerances: +/- .005″

- Max Thickness: Alum 6″ Steel 3-4″

- Operating at 50,000 psi

- Active tolerance control

-

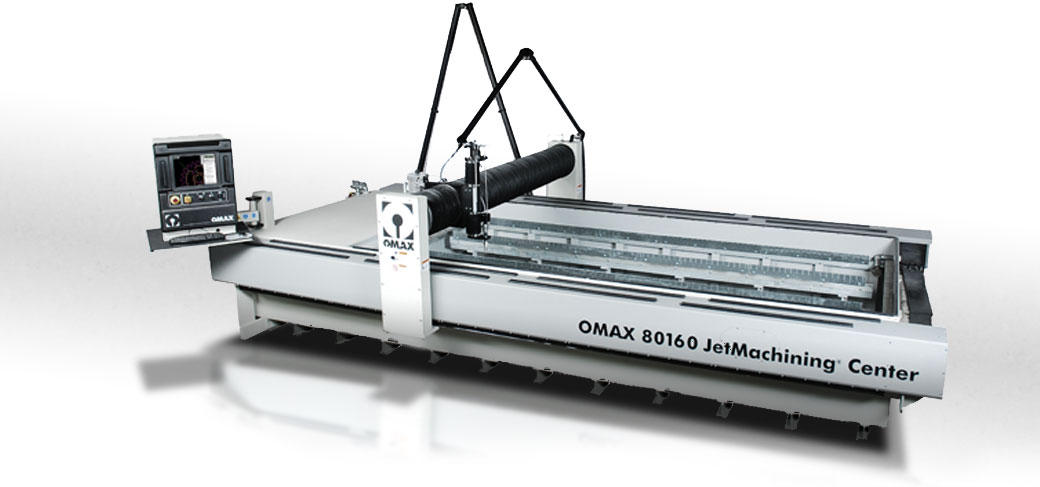

OMAX 80160

- 80″ x 160″ cutting envelope

- Tolerances: +/- .005″

- Max Thickness: Alum 6″ Steel 3-4″

- Operating at 50,000 psi

- Active tolerance control

OMAX 55100

With a completely sealed and protected Ball Screw Drive System, the OMAX 55100 is a robust and reliable workhorse for shops using larger stock. This model comes standard with a OMAX MAXJET® 5 Nozzle and a Bulk Abrasive Delivery System. It rapidly and precisely gets the job done, maximizing both machine time and profit margins.

- Table size of 10′ 6′ x 5′ 5′ (3200 mm x 1650 mm)

- A cantilever Y-axis on a bridge X-axis, with a motorized Z-axis allows for material loading from three open sides

- A work envelope offering an X-Y cutting travel of 8’ 4 x 4’7” (2540 mm x 1397 mm) (100 x 55 inches)

OMAX 80X Series

The OMAX 80160 JetMachining® Center is the only bridge-style model using a completely sealed and protected Ball Screw Drive System. The 80160 is a robust and reliable workhorse for shops using larger stock and needing the convenience of unobstructed material loading provided by the bridge-style Y-axis. This model comes standard with a Bulk Abrasive Delivery System and the OMAX MAXJET® 5i Nozzle. It rapidly and precisely gets the job done, maximizing both machine time and profit margins.

- Table size of 14′ 6″ x 7′ 5″ (4419 mm x 2261 mm)

- Rapid water level control for submerged cutting

- A work envelope offering an X-Y cutting travel of 14′ 0″ x 6′ 8″ (4267 mm x 2030 mm )